May we send our best wishes and seasonal greetings to all of our Customers and Business Partners, with the hope the coming year 2026 bring you and your loved ones good health, happiness and many joyful moments.

Category: Other services

Statement by the Management Board of J.S. Hamilton Poland regarding the laboratory in Gdynia

New Standard PN-EN IEC 62368-1 Added to PCA Accreditation Scope AC 149

We are pleased to announce that the Certification Body of J.S. Hamilton Poland has extended the scope of its PCA accreditation (No. AC 149) to include the PN-EN IEC 62368-1 standard, which defines safety requirements for audio/video (AV), information technology (IT), and telecommunication (ICT) equipment.

The PN-EN IEC 62368-1 standard merges the previous EN 60950-1 and EN 60065 standards, introducing a unified and modern approach to the safety assessment of electronic equipment. It is based on the concept of Hazard-Based Safety Engineering (HBSE), which focuses on identifying and controlling potential sources of risk to ensure user safety.

Why is PN-EN IEC 62368-1 important for manufacturers?

The new approach provides:

- Increased user safety through systematic hazard identification and risk assessment.

- A simplified certification process, as one standard replaces two, facilitating the design and market introduction of convergent devices such as smart TVs, routers, and multimedia systems.

- Greater design flexibility, since the standard defines safety objectives rather than prescriptive technical solutions.

- Compliance with European and global market requirements, as EN IEC 62368-1 is harmonized with the Low Voltage Directive (LVD) and widely recognized internationally.

What this means for our Clients

The extension of our accreditation confirms J.S. Hamilton’s competence in testing and certification of electronic products in accordance with the PN-EN IEC 62368-1 standard.

This enables us to provide even broader support to manufacturers in the areas of conformity assessment, safety testing, and product certification, ensuring compliance with legal requirements and facilitating market entry in both the European Union and global markets.

If you have any questions or concerns, J.S. Hamilton Experts are at your disposal.

Statement from J.S. Hamilton CEO Jan Olszowski

J.S. Hamilton Poland partner in European GridForm project

We would like to announce that J.S. Hamilton Poland has become a partner in the international research project JRP-v04 GridForm – Metrology for efficient grid-forming converters to stabilize future power grids.

The initiative aims to develop precision metrology tools to evaluate so-called grid-forming converters (GFMs) – key components of the energy infrastructure of the future that ensure the stability of grids based on renewable energy sources.

As part of the project, J.S. Hamilton supports activities related to:

- developing test procedures that reflect actual network operating conditions,

- implementing advanced measurement methods,

- construction of new test and calibration stations,

- standardization work in cooperation with organizations such as IEC and CENELEC.

Our company contributes expertise in dynamic measurements, signal analysis and compliance with industrial metrology requirements. These efforts will support the development of services that enable manufacturers and network operators to reliably assess GFM converter performance – both in laboratory and field conditions.

If you have any questions or concerns, J.S. Hamilton Experts are at your disposal.

More about the project: https://www.euramet.org/research-innovation/search-research-projects/details/project/metrology-for-efficient-grid-forming-converters-to-stabilise-future-power-grids

Statement from the Chairman of J.S. Hamilton Poland Jan Olszowski

April at J.S. Hamilton

The end of March marked the beginning of an intensive season of industry events. On March 25, we held the first edition of the Arena Jakości conference, which brought together specialists from the food sector to collectively explore the secrets of food safety. A day filled with presentations, knowledge exchange, and networking provided us with a wealth of inspiration for the weeks ahead.

April kicked off at full speed! From April 1–4, our experts Marcin Achciński and Paulina Tomalska represented us at the 8th International Symposium on Food Packaging in Croatia, sharing their knowledge and experience among international specialists.

During the first week of April, we were also present at the 11th Fish Congress, where Małgorzata Stachowiak delivered a presentation titled “Listeria riding the wave of change”, addressing key issues in microbiological safety in fish and fish products.

On April 8, a series of trade fairs and conferences began, and our team actively participated in:

- WorldFood Poland and NutraFood Poland, where visitors could meet our experts, discuss collaboration, and learn more about food and supplement testing,

- in-cosmetics Global, where we discussed the challenges facing cosmetics manufacturers, especially in terms of safety and regulations,

- Warsaw Pack 2025, where Adam Fotek gave a talk titled “Challenges related to PPWR from the perspective of laboratory testing”, and at the Warsaw PackTech Conference (April 9), addressed the amendment to Regulation 10/2011.

On April 10–11, Małgorzata Stachowiak represented us at the 12th edition of the “Przyszłość Przemysłu Spożywczego” Symposium, where she had the opportunity to present J.S. Hamilton’s approach to food analysis and quality.

On April 24, Marcin Achciński will take part in a webinar organized by the NATUREEF Association, where he will discuss the updates to Regulation (EU) 10/2011 and their significance for packaging manufacturers.

It was a month full of knowledge, presentations, and great conversations. Thank you to everyone we had the pleasure of meeting at events in Poland and abroad.

See you in May!

Happy Easter!

On the occasion of Easter, we would like to extend our best wishes to all our customers and business partners. May this time be full of peace, joy and inspiration for new challenges!

Merry Christmas and a Happy New Year!

May we send best wishes and seasonal greeting to all our Customers and Business Partners, together with prosperity and good health for everyone and their families in 2025.

Happy Easter!

We wish you a healthy, cheerful Easter, ful of peace, spring joy and warmth. May this time be filled with optimism and moments of relaxation with your friends and loved ones.

Merry Christmas and Happy New Year!

We wish our Customers and Business Partners a peaceful time, full of Christmas Eve warmth and special moments spent with your loved ones.

May the coming New Year bring you prosperity and satisfaction.

AGING TESTS – LIGHT AND UV RESISTANCE

Producers and users of products often wonder how long my product will retain its physical, mechanical, strength properties or whether it will retain its external appearance, color and luster during its use and operation.

Xenon and UV aging tests, which we perform at the J.S. Hamilton Poland laboratory, will help determine the characteristics of your products. They are subjected to daylight, moisture and rain and can degrade. Specialists have the knowledge and technical capabilities to verify the effects of the above factors on the surfaces of samples. We carry out accelerated aging tests that simulate the natural atmospheric conditions under which the tested item is used.

We are able to determine how much your products will retain their physical and mechanical properties and appearance. We use methods that check the resistance to conditions in different latitudes of the world, and we subject samples to aging tests that simulate processes occurring after 2,3 or more years.

In our laboratory, we carry out tests according to the following standards:

- PN-EN IEC 60068-2-5:2018 – Environmental tests – Part 2-5: Tests – S test: Mapping of solar radiation occurring on the earth’s surface and guidelines for testing the effects of solar radiation and weather conditions,

- PN-EN ISO 4892-1:2016-06 – Plastics – Methods of exposure to laboratory light sources – Part 1: General principles,

- PN-EN ISO 4892-2:2013-06 – Plastics – Methods of exposure to laboratory light sources – Part 2: Xenon arc lamps,

- PN-EN ISO 16474-1:2014-02 – Paints and varnishes – Methods of exposure to laboratory light sources – Part 1: General remarks,

- PN-EN ISO 16474-2:2014-02 – Paints and varnishes – Methods of exposure to laboratory light sources – Part 2: Xenon arc lamps.

- PN-EN ISO 4892-3 Plastics – Methods of exposure to laboratory light sources – Part 3: UV fluorescent lamps.

Depending on the research program, appropriate min. parameters are selected :

- number and length of cycles

- light filter

- irradiation level

- length of light and dark periods

- sample moistening (spraying)

- temperature during exposure to light as in the darkness

- relative humidity in the chamber during exposure to light as in darkness

The test should be conducted until the intended exposure time or radiation dose is achieved. After the test, the samples are subjected to visual and dimensional inspection, strength tests and functional tests.

In case of questions or concerns, J.S. Hamilton Experts remain at your disposal.

Feel free to contact us by email: siemianowice-marketing@jsh.com.pl or use the contact form.

J.S. Hamilton Poland awarded the Compass of Standardization!

We are very pleased to announce that on May 18, at a ceremony in Warsaw, our company was awarded the Compass of Standardization award granted by the Polish Committee for Standardization (PKN). We would like to thank Ms. Ewa Zielińska, President of the company, and the entire PKN for appreciating the role of J.S. Hamilton Poland in supporting the Polish standardization system.

The award was received on behalf of our company by Marcin Ficek, Member of the Management Board of J.S. Hamilton Poland, and Hanna Wachowska, Director of Scientific Support and Cooperation with Laboratories. The PKN “Compass of Standardization” award has been granted since 2015. Its purpose is to honor individuals and institutions in recognition of their achievements in supporting standardization, including: outstanding achievements and contributions to Polish standardization, promotion of the voluntary standardization system, significant contributions to promoting a pro-standardization attitude among the public, and exceptional activity in the standards development process.

The Polish Committee for Standardization (PKN) is a national standards body, which is responsible for organizing standardization activities. PKN is not a government administration body, it is a public law entity. It operates under the Standardization Act of September 12, 2002.

J.S. Hamilton Poland Sp. z o.o. has been actively involved in standardization activities for many years and has made a valuable contribution to standardization covering many branches of the economy. The company. has been very active and involved in the process of developing Polish Standards within the framework of standardization topics. Since 2013, PKN within the Food, Agriculture and Forestry Sector has signed contracts with J.S. Hamilton Poland Sp. z o.o. for the development of 32 Polish Standards in the form of standardization topics and one contract within the framework of custom work.

The reliability, stability and professional approach to the duties performed by J.S. Hamilton Poland Sp. z o.o. guarantee a high level of service performance. The long-standing experience and commitment to the development and promotion of standardization in so many areas is highly appreciated by the Polish Committee for Standardization.

NIAS in your food

Pizza straight from the oven, your favorite soda, a cake as if it came from a neighborhood pastry shop – all you have to do is go to the supermarket and pick out your favorite product. Few people think about whether potentially harmful substances from labels or packaging are leaking into our favorite foods. J.S. Hamilton of Gdynia is the first company in Poland to have equipment that can check this thoroughly.

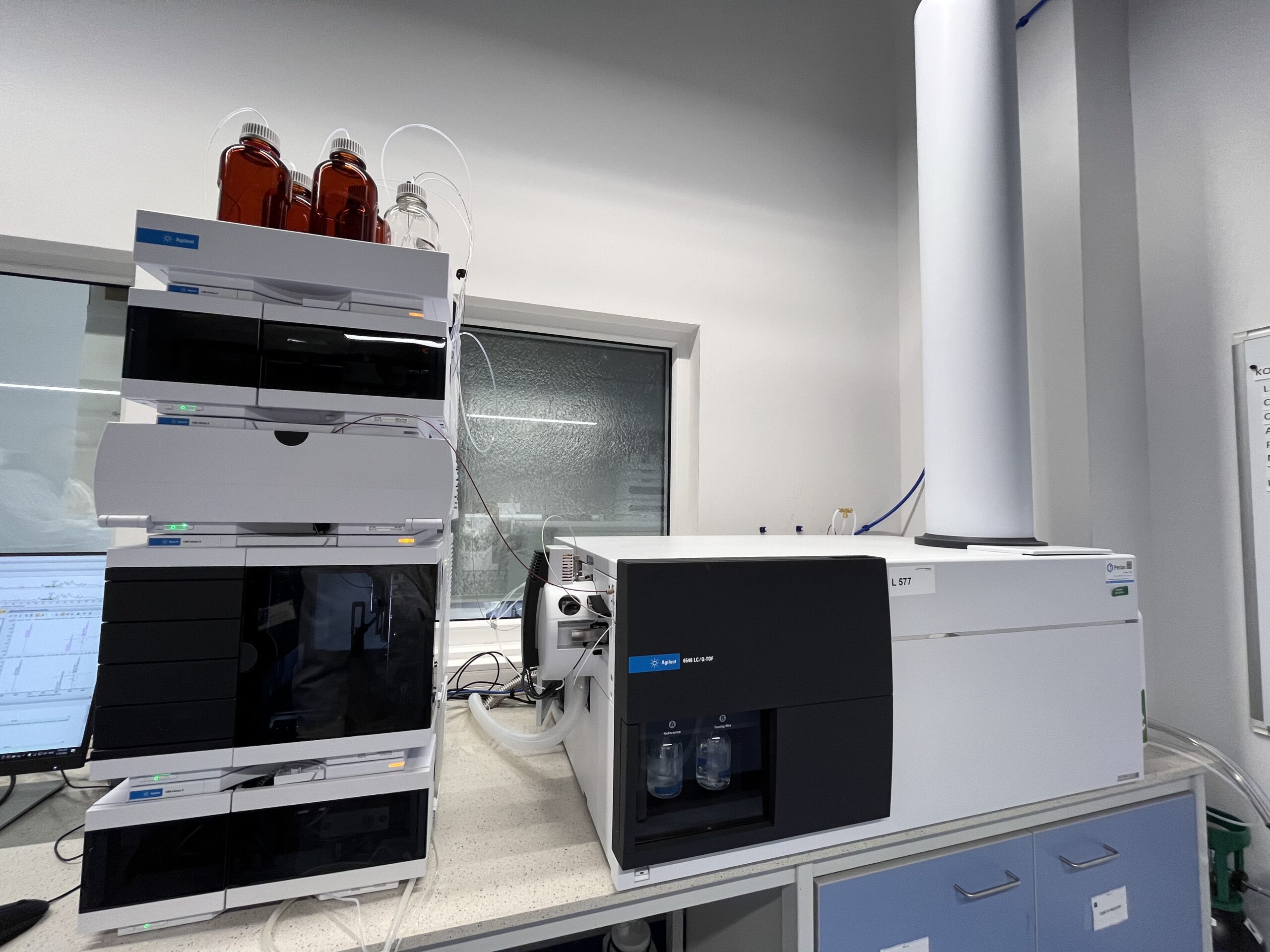

Worth 2 million zlotys, the liquid chromatograph coupled to a time-of-flight analyzer mass detector (LC-QTOF-MS) is a device that has not been used commercially in our country until now. Companies wishing to verify what non-intentionally added substances (NIAS), e.g., ingredients in paints and varnishes, are in the products we consume have had to turn to the few testing laboratories in the West that perform such analyses.

– As a leader in testing food contact packaging, we provide a unique opportunity in our country to verify the presence of substances that were previously difficult to detect. For our customers, as well as ordinary consumers, this is very good news,” says Michal Pestka, Consumer Product Testing Director, J.S. Hamilton Poland.

Additives we don’t know about

Non-intentionally added substances (NIAS), e.g. ingredients in paints and varnishes, is a problem that more and more food manufacturers are struggling with. The requirements here are imposed by law, such as Regulation (EC) No. 1935/2004, Regulation (EU) No. 10/2011 – on materials and articles intended to come into contact with food marketed in the EU, but growing public awareness is also playing an increasingly important role.

– Speaking of food and the standards that packaging must meet, let’s remember that it’s not just about legal requirements. The target consumer, year after year, is becoming more and more aware of the impact on his health, for example, components of paints and varnishes that penetrate into food, and is increasingly choosing packaging that guarantees the safety of the products stored in it. This makes it all the more important that an apparatus that allows for the accurate analysis of substances (NIAS), is located in our country, adds Michal Pestka.

Finding the needle in the haystack

The analytical possibilities offered by Hamilton’s new chromatograph are difficult to overestimate. The dynamically developing market of materials and products intended for contact with food forces, more and more flexible approach of analytical laboratories to the offered tests. The research topics require the use of state-of-the-art analytical methods, which the new chromatograph guarantees.

– Our apparatus allows quantitative and qualitative analysis of the content and migration of organic compounds in a wide range of molecular weights. The most important advantage of the purchased instrument (LC-QTOF-MS), is the much higher resolution compared to the LC-MS/MS already in use. At present, it is the latest analytical technique used for commercial research; in addition to migration studies, it is used in biological and medical research, argues Adam Fotek, research expert at the J. S. Hamilton Poland research laboratory.

Science in cooperation with business

The complex composition of plastics and paper/cardboard, including the use of various additives in two-plastics (such as antioxidants, plasticizers, dyes, adhesives, stabilizers) requires that the testing laboratory be able to provide as much information as possible about substances potentially migrating from packaging. Therefore, in implementing the new equipment, Hamilton also relied on research work. Grzegorz Jasik, analysis expert, J. S. Hamilton Poland, is participating in the 6th edition of the “Implementation Doctorate” program at the Faculty of Chemistry, Gdansk University of Technology.

– The aim of the Implementation Doctorate is to develop and validate a non-targeted chromatographic method based on a liquid chromatograph with a quadrupole detector-type time-of-flight analyzer (LC-QTOF-MS), to create a procedural approach for the identification of (non-)intentionally added substances (IAS/NIAS) and to adapt the technique to routine laboratory work. The result of the work will allow, on the one hand, to catch up with the largest laboratories in the European market, to build a leadership position, and above all to bet on Polish specialists in this field, on the other hand, the entire scientific output during the implementation PhD, will allow the evaluation of potentially migrating compounds, as well as their decomposition products (e.g. as a result of high temperature) – which will allow a broader and more accurate analysis of product safety, adds Grzegorz Jasik.

Article by J.S. Hamilton expert in the World of Cosmetics Industry

The latest issue of the magazine features the article “Quality in in vivo testing of cosmetic products with sun protection factor (SPF).”

World of the Cosmetics Industry, is a specialized Polish quarterly trade magazine aimed at cosmetics industry manufacturers and suppliers, offering products and services to the cosmetics industry. In her article, Karolina Dziąbowska, UV Section Manager at J.S. Hamilton, presents aspects of quality control and safety of products with SPF.

Thanks to the article, you can learn what characterizes quality in research with sun protection and how it is important for the health and safety of consumers.

We invite you to read it here.

J.S. Hamilton focuses on entrepreneurship

Creating entrepreneurial attitudes, promoting the principles of optimal management, as well as showing young people possible directions of development in higher education, are the reasons why the Maritime University of Gdynia organized the Knowledge about Management and Economics competition. On December 8, 2022, at the Faculty of Management and Quality Sciences of the Gdynia Maritime University, the award ceremony of the winners took place. The partner of the event was J.S. Hamilton.

A total of 126 high school students from the Pomeranian, Warmian-Masurian and Opole provinces entered the competition. The competition was held under the honorary patronage of His Magnificence Rector Prof. Dr. Eng. Capt. Adam Weintrit and the Mayor of Gdynia Dr. Wojciech Szczurek. During the speech, Magdalena Smolarska, People & Culture Director, and Wojciech Paruzel, Operations Director, introduced the contestants to the possibilities of participating in student internships and apprenticeships organized by the company, which are a great foundation for further development.

For many years, J.S. Hamilton has been opening its doors to students who want to gain first-hand experience and learn about the specifics of working in the laboratory. Read more about internships, apprenticeships and employment in the Career.

We would like to extend our heartfelt congratulations to all the Laureates! To the authorities of the University, we thank you for the opportunity to participate in the event and congratulate you on an excellent undertaking!

For a full photo report of the event, visit the Organizer’s website.

IECEx Assessment Scheme

The IECEx is a system for confirming the correct and safe construction of explosion-proof devices. Documents issued by this schema are globally recognized in all countries participating in the IECEx system. In Europe, IECEx certification is not obligatory, but it opens the door for the manufacturer to distribute its products to the world in the entire industry related to potentially explosive atmospheres.

The IECEx certification and testing scheme is based on the TC31 technical committee. The first concept of the organization was created in 1992, so that already in 2000 the first IECEx tests could be carried out and the first IECEx CoC certificate issued. Since August 2003, the system has been operating on the basis of a public website. The language of the IECEx system is English. All issued documents in the scheme (IECEx CoC certificates, ExTR reports, QAR quality system assessments) are publicly available at www.iecex.com, which makes the system transparent because each user can at any time confirm the compliance of the device used with the requirements set by the IECEx organization. As in Europe, the most important document accompanying a product is the EU Declaration of Conformity, in the case of the IECEx system, the most important is the certificate, which is available online all the time.

By 2021, 36 countries had joined the IECEx scheme, Poland joined in 2008. J.S Hamilton Poland has the status of an ExCB certification body and an ExTL research laboratory,

The overall structure, scope of activities, workflows and responsibilities are presented in the IEC documents published on the website www.iecex.com

The ExCB certification body cannot exist without the associated ExTL testing laboratory. Likewise, a test laboratory cannot exist without being linked to an ExCB unit.

ExCB and ExTL J. S. Hamilton are located in Siemianowice Śląskie, our scope of activity is IECEx testing and IECEx certification.

The test reports (ExTR) issued by the laboratory (ExTL) are verified by the ExCB unit. The ExCB unit supervises the tests (scope and test program) performed by ExTL

The IECEx CoC certificate can be issued after the unit (ExCB) carries out both laboratory tests (ExTL) and the assessment of production quality assurance in accordance with the requirements of ISO / IEC 80079-34.

We specialize in testing and IECEx certification of electrical Ex devices and components such as cable entries, cable glands, insulators, empty Ex d enclosures, junction boxes, lighting fixtures, electric motors, combustion engines, transformers, sensors, transducers, barriers, and a whole range of non-electrical Ex devices such as pumps, mixers, dissolvers, mechanical and pneumatic transport devices, valves, gears, brakes, skids, and many others … All in compliance with the following standards:

IEC 60079-0 – electrical equipment

IEC 60079-1 – flameproof enclosures Ex d

IEC 60079-2 – pressurized enclosures Ex p

IEC 60079-7 – incerased safety Ex e

IEC 60079-11 – Ex i intrinsically safe equipment

IEC 60079-15 – Non-sparking equipment Ex n

IEC 60079-18 – encapsulation Ex m

IEC 60079-25 – intrinsically safe systems

IEC 60079-26 – category 1 equipment, EPL Ga

IEC 60079-28 – optical radiation Ex op

IEC 60079-31 – equipment for dust atmospheres Ex t

IEC ISO 80079-36 – Ex h non-electrical equipment

IEC ISO 80079-37 – Ex h non-electrical equipment

https://www.iecex.com/information/excbs/httpwww-iecex-comdirectorybodiesbodies1-aspid5/

We invite you to cooperation!

J.S. Hamilton Group strengthens its position on the Serbian TIC market by acquiring majority stake in Institut za zaštitu na radu a.d.

In line with J.S. Hamilton vision of becoming a market leader in all geographies in which it operates, both through organic growth and M&A, the acquisition of Institut aims at strengthening the company’s leading position in the Serbian TIC market, after the last year acquisition of Serbian SP Laboratorija in January 2020.

Our investments aim to strengthen the position of J.S. Hamilton as a market leading network of laboratories and inspection companies in CEE. We see significant growth potential of the Serbian market in the coming years, mainly due to the alignment of Serbian regulations with EU legislation – says Dawid Dolata, CEO at J.S. Hamilton Group.

The transaction concerns approx. 70% of shares in one of the key players on the TIC market in Serbia with headquarters in Novi Sad and three branches in Nis, Sabac and Kragujevac. Institut was founded in 1960 as a State-owned company. In 2002 Government initiated the privatization and current owners, who at the time worked at Institut, acquired 70% of issued shares in the privatization auction process and became new majority owners; In 2012 the current owners acquired the remaining shares. Today the company is led with operational excellence by top management and employs team of c.100 qualified experts and has state-of-the-art equipment. Institut brand is perceived as well-known not only in Serbia but entire CEE.

Local market know-how and highly qualified personnel are Institut’s key assets. The cooperation will enable us to combine this unique knowledge with the experience of J.S. Hamilton in Europe. This guarantees our clients the highest quality and professionalism. At the same time, our company will gain new development opportunities – explains Zeljko Tomic, Managing Director at Institute.

Institut mainly offers laboratory tests including environmental, food and mechanical / physical tests, certification (occupational safety, engineering) and inspection services, what complements SP Laboratorija offer concentrated mainly on food testing.

J.S. Hamilton Group

J.S. Hamilton is a group of companies located in CEE, providing a wide range of specialized services for industry, trade, transport, distribution and storage. The company offers a wide range of accredited laboratory analyzes of food, cosmetics and household chemicals, pharmaceuticals, packaging and industrial products, liquid and solid fuels and chemicals, environmental samples (water, sewage, waste, soil, etc.) as well as environmental documentation, consumer tests and testing of electronic and electrical equipment.

Voluntary Certification J.S. Hamilton

Voluntary Certification is an assessment process to confirm that a certain characteristic of a product or material has been met. It was developed on the basis of standards applicable in this area and in nomenclature is a program of type 2 according to ISO/IEC 17067.

The result of the assessment carried out for the customer is obtaining a certificate and an individual mark of conformity.

Certificates issued by the Product Certifying Body of J.S. Hamilton confirm the fulfilment of obligatory requirements (compliant in accordance with applicable laws, standards) and/or voluntary properties of the assessed product.

Current certification options can be found here.

Do you have any questions? Contact us

For the safety during the coronavirus pandemic

Due to the increasing number of coronavirus infection cases in Poland, we endeavour to do as much as we are able to ensure the safety of our contractors, employees and their families. J.S. Laboratories Hamilton are working seamlessly today. We carry out all analyzes on a regular basis, maintaining business continuity, while implementing measures to minimize the risk to our employees’ health.

We have taken many measures to protect laboratory employees who deal with microbes on a daily basis, so they maintain the highest standards of hygiene and personal protective equipment.

Now we have added:

- we increased the frequency of disinfection of working surfaces with specialized protection facilities, including regular smoke and ozonation,

- we supplied laboratories with additional protective equipment – gloves, face masks, paper towels,

- we introduced shift work to minimize large groups of people; in addition, we start work on Sunday for people who have concerns about being in gatherings of people

- we trained employees collecting samples in the field of personal protection and ordered strict compliance with our clients’ internal procedures.

We have also introduced protective work rules for the office employees of J.S. Hamilton:

- the vast majority of our employees stay at home, caring for their own and their loved ones’ health, providing work remotely, using teleconferences, instant messengers, telephones,

- we canceled all direct meetings with clients in Poland and abroad,

- we limited the access of people from outside the company to the minimum necessary only in designated areas, where we installed dispensers with disinfectant liquid and warnings.

We emphasize that today the coronavirus epidemic has no effect on the current activities of J.S. Hamilton and we still guarantee full continuity of services. We closely monitor the current situation to be able to respond flexibly to changing conditions, including logistics or communication.

Today, security is a priority for all of us, we are constantly striving to provide services at the highest possible level, while maintaining emergency protection measures.